-

Hot

Dynamic classifier

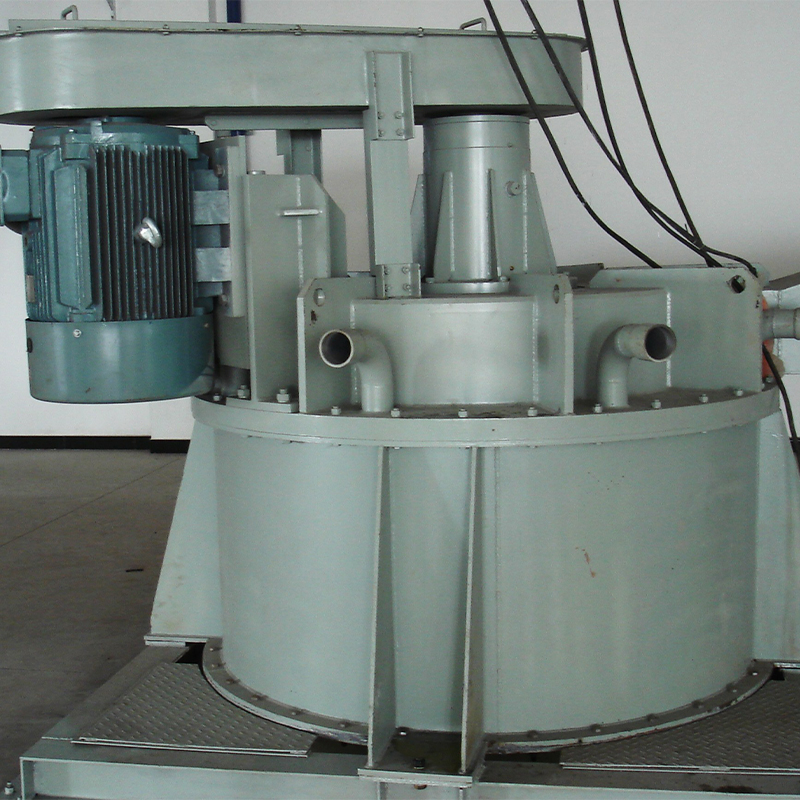

DCC Dynamic Classifier Our patented DCC series of dynamic classifiers are so-called air classifiers or turbo classifiers. The wide range of cut points and easy and exact adjustment of the cut point let this type of air classifiers dominate the market of powder processing for almost every product. A further advantage is the “hard classifying characteristic”. That means, by variations of the feed rate the cut point almost does not shift. This performance predestines the dynamic classifier to be used in grinding-classifying-circuits. It has the following advantages: -Airborne principle of design -The cut point does not shift even if the feeding is fluctuated. -Clean cut point without oversize particles -Easy adjustment of cut point -Suitable almost for all kinds of powders classification Technical data: The feed rate is in a range of 0.3t – 20t/h The cut point ranging from D97 3µm-150µm Application: mineral fillers, chemicals, pigments, quartz, abrasives, ceramic, fly ash, metal powder, graphite, mica, foodstuff, pharmacy…etc.

Send Email Details -

Hot

SSC static classifier

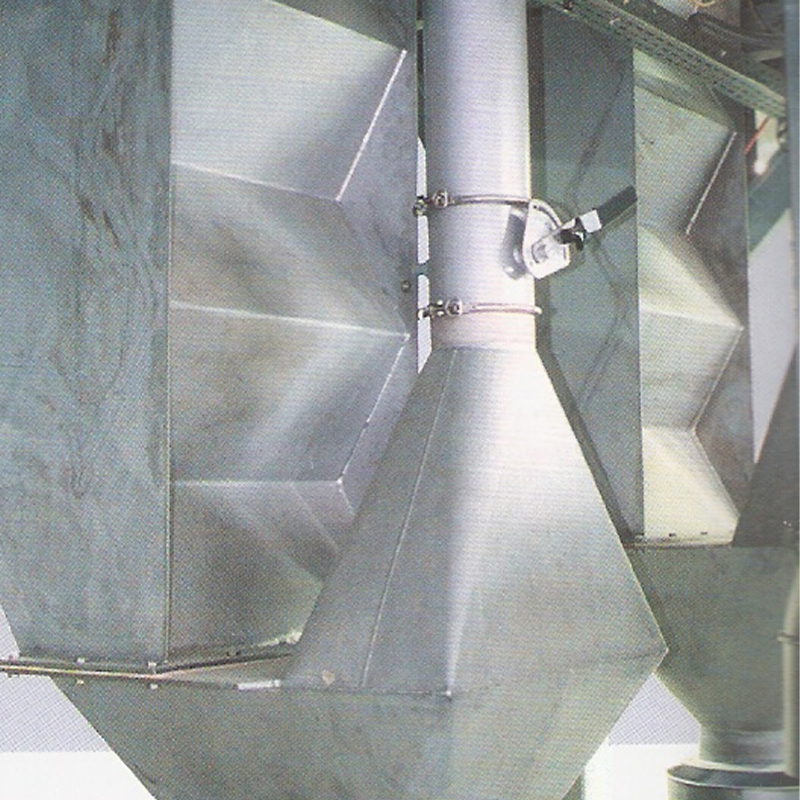

The SSC Static Classifier The SSC static classifier is a newly developed classifier with free vortex flow. As its name indicates, there are no rotating parts. Therefore, it is easy to be wear-protected for hard mineral processing. The classifier users find that the high-speed rotors are damaged easily under strong impact and abrasion, consequently, contaminating the products. This static classifier is approved to be the best solution for eliminating contamination. Furthermore, the optimized design of spiral flow and rinsing air guarantee the output of fine products free from oversize particles as well as coarse fraction clean. The SSC static classifiers can achieve a sharpness of cut point nearly as good as much more expansive multi-wheel classifier. The advantages as follows: -This classifier has neither rotor nor motor: low investment -Static classifier has no motor: low running cost - Easy to be protected with ceramic tiles or PU for iron-free production. -Easy maintenance on-site: low maintenance fee. -Sharpness of cut point as good as those of the most expensive multi-wheel classifier. - For fines collection a cyclone is sufficient, filters are not necessary. In the classifying process this kind is often used for taking away the dust from the end product to get clean particles. It is also used to separate the small amount of very big particles from the fines. When it is used for pre-classification it can optimize the main classifying process by rejecting either fines or coarse resulting in high classifying efficiency. Applications: •Suitable for classifying hard minerals, such as silica, quartz, pegmatite, feldspar, granite, ceramics…etc. •Suitable for classifying food stuff or spices particularly those with high content of fat. •Suitable for classification of flaky particles i.e. flaky metal effect pigments, talc, graphite ...etc. •Working in high temperature conditions which classifier with wheels cannot stand. Technical data: The feed rate is in a range of 20kg to 12000kg/h The cut point ranges from D97 5µm-120µm

Send Email Details -

Hot

Multi-wheel classifiers

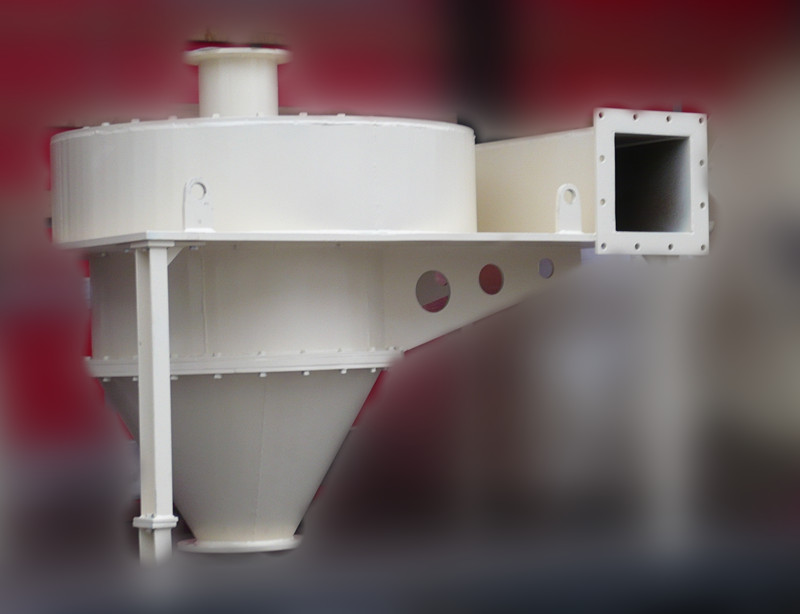

The Multi-Wheel Classifiers Our IMC Multi-wheel classifier series have been developed especially for ultra-fine products. With the IMC series we extended our program of the DCC series. The multi-wheel classifiers have the principle similar to the dynamic classifier, but the wheels are in horizontal arrangement. As we know, the throughput of the product is related to the surface area of the wheel whereas the fineness of the product related to the speed of the wheels. The main point of its development was to achieve high throughput rate of ultra-fine end products, so a good sharpness, high efficiency and low specific energy consumption with highest output were set as the guideline for this target. We have achieved these criteria by optimizing the dynamics of air flow, the material resistance and the multi-wheel concept. Our IMC multi-wheel classifiers have the following advantages: -High output of ultra-fine products - Sharp cut point without oversize particles -High efficiency and low specific energy consumption -Robust construction for long serving life Technical data: The feed rate is in a range of 1t-50t/h The cut point ranges from D97 4µm -200µm Th Applications: Mineral fillers, ceramic fillers, chemical products, plastic powder, pigments and toner, graphite, mica, metal powder, foodstuff, pharmaceuticals and so on.

Send Email Details -

Hot

Static classifier

The SSC series of static classifiers: In cooperation with the specialist of Germany we have invented a new type of static classifier. This SSC series of static classifiers is designed with the principle of free vortex flow. As its name indicates, there are no rotating parts. Therefore, it is easy to be equipped for wear protection to achieve iron-free product. Additionally, it adapts to special requirements and can operate with hot gas or cooling air. The optimal spiral flow in combination with an efficient rinsing and quick discharge of the coarse particles guarantees a fine product free of oversize particles as well a clean coarse fraction. The SSC static classifier can achieve a sharpness of cut point nearly as good as a much more expansive multi-wheel classifier. The product is fed airborne, that allows an inline production with a mill or a dynamic classifier, i.e. to perform a two-stage classification. The airborne principle enables a closed air circulation. For fines collection a cyclone is sufficient, filters are not necessary. Two simple possibilities of adjustment in combination with a quick change of one or two parts enable the classification to cover a wide range of cut points. According to the mentioned above advantages the SSC classifiers are suitable for a very wide field of applications. It is predestined for Process Applications: · De-dusting (to get clean particles without dust) · scalping (to separate a small amount of very large particles) · pre-classification (to optimize the main classification process by rejecting either fines or coarse) Product Applications: abrasives (i.e. pure quartz, feldspar ...etc.) food (especially with high content of fat) metal effect pigments (“flakes”, must be carefully handled) high temperature material (carbon black, chemicals) Technical data: The feed rate is in a range of 20kg to 6000kg/h The cut point ranges from D97 5µm-120µm

Send Email Details -

gravitational classifier

The gravitational Classifier The gravitational classifier follows gravity principle. It has a zigzag shape structure without rotating parts and motor. This classifier is applied to the classification of 0.3mm-10mm fractions. The cut point is adjustable with high sharpness. The zigzag tubes can be installed in a few numbers for capacity ranging from a few kilograms up to hundred tons of products to satisfy the required capacity. Additionally, the gravitational classifiers are easy to operate in classifying light material or in separating mixture of different material. The advantages as follows: -gravitational feeding -no rotating parts -low maintenance rate -the capacity increased by adding tubes -the cut point is adjustable Technical data: Cut point: D97 0.3mm – 10 mm Feed rate: 10kg-200 tons /h Application: food industry, solid waste treatment,construction waste, mixture of material with different gravity and dust removing from coarse fractions.

Send Email Details -

The lab Desk Classifying Unit

The Lab Desk Classifying Unit is an advanced and versatile equipment designed specifically for particle classification and analysis in laboratory settings. It consists of a complete classifying system, which is composed of one dosing screw, one dynamic classifier,one static classifier and a filter followed by a high pressure fan. The Classifying Test Station is absolutely necessary for new material development and scientific researchers involved in various industries, including, materials science, pharmaceuticals and chemical engineering and environmental monitoring...etc. With its advanced technology and robust design, the Lab Desk Classifying Unit provides accurate and reliable results, enabling users to make informed decisions in either engineering or research project. The Lab Desk Classifying Unit can be used not only for classifying test and new material researches, but also for production of high value-added products, such as metal powder, toners and chemicals...etc. Furthermore, by one step of classification on this test station the users can achieve products of special particle size distribution for specific application. Cut point: D97 3-120 µm feed rate: 50-500kg/h Application: For classification of almost any kind of powder products.

Send Email Details -

No wheel classifier

No wheel classifier No wheel classifier means there is no rotor in the classifying chamber. No wheel classifier is also named static classifier. Following free vortex flow principle we have developed such a classifier. With cutting-edge technology we solve the critical problem of classifying silica, pure quartz and many other hard minerals. The feed material is transported pneumatically into the classifying chamber. The mass flow goes along the guide vanes to form a spiral flow where the classification takes place. The rinsing air comes from the bottom enhances the classifying efficiency. The sharpness of cut point of the product from no wheel classifier is comparable to that coming from the much more expensive multi-wheel classifier, which allow it stand out among the many other types of classifiers in dealing with quartz and many other hard minerals. The advantages: -This rotor-less classifier does not need a motor and complicated structure saving investment. -saving a motor means saving running cost. -Easy to use different anti-wearing material for protection. -Easy repairing on-site, no need to send back to factory saving maintenance time and cost. -Multi-functional: suitable for either take away dust from the product to get clean fractions or eliminate small amount of big particles from the product -Used for pre-classification to make the main classification more effective. -Suitable for extreme working conditions, such as high temperature. Application: For hard and abrasive minerals (quartz, pegmatite, feldspar, granite, ceramic material), abrasive products, flaky metal powder, foodstuff with high content of fat, carbon black...etc. Technical data: Processing capacity: 20 kg/hr to 12000 kg/h. Particle size range: D97 5 to 150µm

Send Email Details -

turbo classifier

The turbo classifiers belong to so-called air classifiers or dynamic classifier. It consists three parts: the classifier chamber at the top with one wheel of vertical arrangement, the secondary air inlet in the middle and the lower part, a cone for feeding and discharging of the reject. Owing to the double sealing there is no oversize particles in the products. Meanwhile, the wide range of cut points are easily and exactly adjusted by the speed of the wheel control with a frequency converter. Therefore this type of air classifiers dominate the market of powder processing for almost every product. A more important advantage is the “hard classifying characteristic”. That means, even though variations of the feed rate occurs the cut point almost does not shift. This performance predestines the turbo classifier to be used in grinding-classifying-circuits. Technical data: The feed rate is in a range of 0.3t – 20t/h The cut point ranging from D97 3µm-150µm Applications: Mineral fillers, chemicals, pigments, paint, toner, silica, ceramic, abrasives, metal powder, foodstuff, pharmaceuticals, fly ash, solid waste...almost all kind dry powders products.

Send Email Details -

Single Wheel Classifier

The single wheel classifier The single wheel classifier is our new invention. It belongs to air classifier category. The classifying wheel is driven directly or by belt decided according to the motor size. The prominent advantage is the “hard classifying characteristic”. That means even though the fluctuation of the fed material the cut point of the product dose not shift, therefore, this kind of single wheel classifier shows a good combination with a grinding machine. Additionally, the single wheel classifier presents a wide range of cut points, which can be adjusted easily and exactly with frequency converter. Owing to the optimized sealing technology the products always have a sharpness of cut point without oversize particles. The singe wheel classifier has found wide application in powder industry. The advantages: -The cut point is adjusted easily via frequency converter -Double sealing design guarantees clear cut point without oversize particles -Dominating the power classification market and usable for a variety of different materials. -The most important point is “hard classification characteristics”, that means the variation of feed rate does not shift the cut point. -To work with a ball mill to form a grinding and classifying system to increase the grinding efficiency -Simple structure for easy operation and maintenance -Sturdy structure ensures durability and long-time service Application: The single wheel classifier characterized by exact cut point and easy operation dominates the classifier market almost covering all kinds of powder products.

Send Email Details -

ultra-fine classifier

Ultra-fine Classifier With the rapid development of powder technology the powder products, particularly the mineral fillers are required finer and finer. Apart from the mills that have to be improved to bring about more and more fines, an ultra-fine classifier is also the key part to take out the fines from the ground material as much as possible. Facing the market challenge we optimizes the details of our dynamic classifier to realize the purposes. As we know the fineness of product depends on the speed of the classifier wheels whereas the output is determined by the surface of the wheel. So we integrate numerous classifying wheels in horizontal arrangement that are controlled by a single frequency converter. This innovated ultra-fine classifier contributes a high throughput of superfine products. The ultra-fine classifier is characterized by -Sharp cut point without oversize in the product -Easy adjustment of cut point by variation of the wheel speed. -Numerous wheels in one classifier for high throughput. -Easy operation with high performance. Application: Mineral fillers, chemicals, pharmeceuticals, pigments, toner, cosmetics, foodstuff, graphite, mica,..etc. Technical data: The cut point ranging from D97 4-200µm The feed rate ranging from 1-50t/h

Send Email Details -

ultra-big classifier

The ultra-big classifier is designed for large mass flow rates, it offers high processing volumes. Users dealing with mineral fillers, cement additives, fly ash, slags, industrial solid waste and so on require large quantity of products to fulfill their production needs. The ultra-big classifier just satisfies the demand. The innovative design classifier wheels with guide vanes enhances the dispersion and classification efficiency. This ultra-big classifier is designed to handle fine or medium coarse products. With optimized sealing device there is no oversize in the output. The fine powder outlet employs a dual channel system for fast discharging the product to ensure complete smooth process. The ultra-big classifier exhibits the following advantages: -Large air flow rate brings about large quantity output -The product fineness is ranging from fine to medium coarse -Hard classification characteristics, ie. only minimal shift in the cut point despite feed variations. The processing capacity ranges from 25 to 200 tons per hour, with a cut range of D97 25-200 microns. It is suitable for classifying fly ash, slags, fine cement, coal powder, material fillers, construction waste and tailings.

Send Email Details -

BSC Basket separator

BCS Basket Separator The BCS separators are equipped with a rotating basket. Similar to the DCC series of dynamic classifier, the cut point is adjusted by the speed of the rotating basket, which guaranties a “hard classifying characteristic”. That means, by variations of the feed rate the cut point does not shift. These basket separators are designed to handle high air flow rates with big mass, with a target to classifying large quantity of fine or medium coarse products, such as fly ash, slags, fine-cement, mineral fillers, tailing from ore dressing, industrial solid waste etc. The advantage: -Capability to handle a variety of products with feed rate from 30t to 200t per hour. -Guide vanes leading to efficient dispersion and efficient classification. -Optimal sealing guarantees sharp cut point and prevents from oversize particles. -Hard classifying characteristics stabilizing the set cut point. Technical data: The feed rate is in a range of 25-200t/h The cut point ranges from D97 25µm -200µm Application: mineral fillers, fly ash, slags, construction material, solid waste, fine cement … etc.

Send Email Details