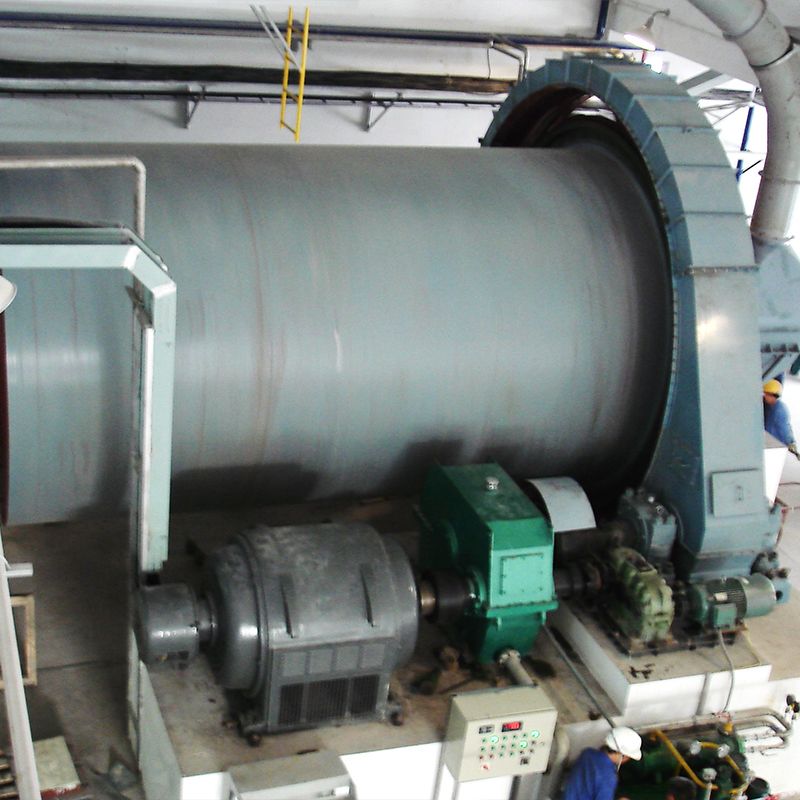

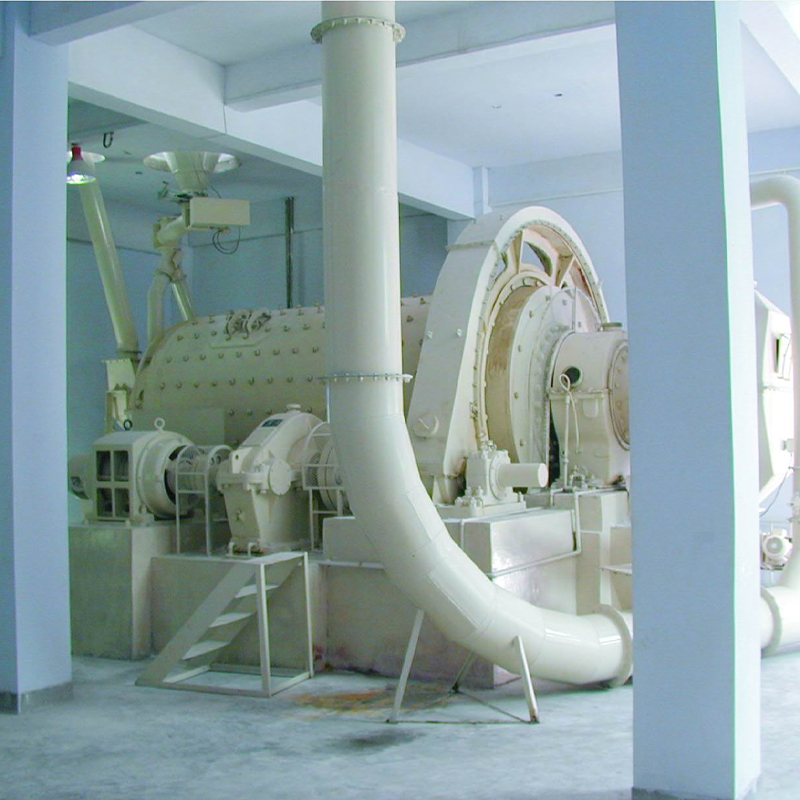

Ground silica ball mill

Brand IVA Shanghai

Product origin Shanghai

Delivery time 90-120days

Supply capacity 10

Ground silica ball mill

Due to low-speed rotation the ball mill is an ideal device for grinding hard and abrasive minerals, such as silica, quartz, feldspar, pegmatite, ceramic raw material and other hard minerals. The inside of the drum is well protected with alumina lining or silexite blocks for iron-free production. Furthermore, our unique dry grinding ball mill of tailor-made design to work together with our newly invented static classifier becomes the best economic solution for processing silica, pure quartz as well as other hard minerals.

The advantages as follows:

-Energy saving design

--Iron-free production

-Consistent quality

- Environment friendly and safety

The features:

- All the ball mills for ground silica and pure quartz are tailor-made based on the grindability of raw material and the product requirements.

- The drum has an optimal L/D ratio that prevents the material from over-grinding.

- The ground silica ball mill de-dusting through an opening at the end of the mill ensures optimal aspiration and cooling.

- Inside of the ball mill Al2O3 bricks or Silex bricks are used as liner for iron-free grinding.

- Ceramic balls or flint pebbles makes the products free from iron contamination.

- At the end of the ball mill there a sieve to collect the broken grinding medium.

- The installed motor of the ground silica ball mill matches the grinding energy perfectly resulting in energy saving.

- Cylindrical roller bearing and sliding bearing with lubrication system are optional.

- Solid construction of the ground silica or quartz ball mill offers long-lasting service with low maintenance cost.

- Flexible installation of the drive station to fit the limited space is possible.

- An level indicatior is installed at the outlet of the ground silica ball mill works automatically in the production line.