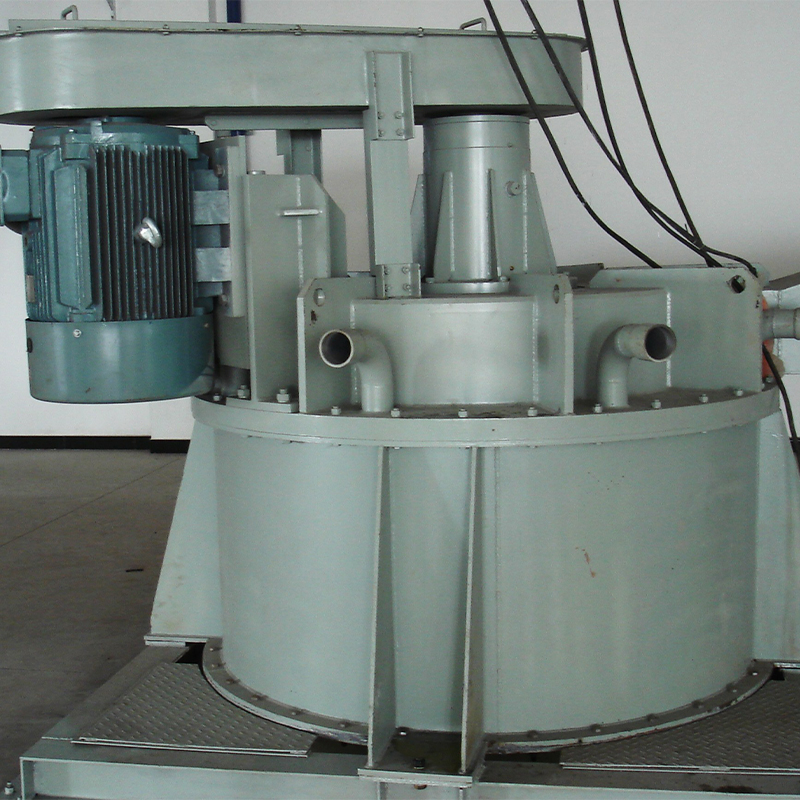

Multi-wheel classifiers

Brand IVA Shanghai

Product origin Shanghai

Delivery time 120 days

Supply capacity 10

The Multi-Wheel Classifiers

Our IMC Multi-wheel classifier series have been developed especially for ultra-fine products. With the IMC series we extended our program of the DCC series. The multi-wheel classifiers have the principle similar to the dynamic classifier, but the wheels are in horizontal arrangement. As we know, the throughput of the product is related to the surface area of the wheel whereas the fineness of the product related to the speed of the wheels. The main point of its development was to achieve high throughput rate of ultra-fine end products, so a good sharpness, high efficiency and low specific energy consumption with highest output were set as the guideline for this target. We have achieved these criteria by optimizing the dynamics of air flow, the material resistance and the multi-wheel concept.

Our IMC multi-wheel classifiers have the following advantages:

-High output of ultra-fine products

- Sharp cut point without oversize particles

-High efficiency and low specific energy consumption

-Robust construction for long serving life

Technical data:

The feed rate is in a range of 1t-50t/h

The cut point ranges from D97 4µm -200µm

Th Applications:

Mineral fillers, ceramic fillers, chemical products, plastic powder, pigments and toner, graphite, mica, metal powder, foodstuff, pharmaceuticals and so on.

Features:

· Similar to dynamic classifier the multi-wheel classifier is of airborn principle.

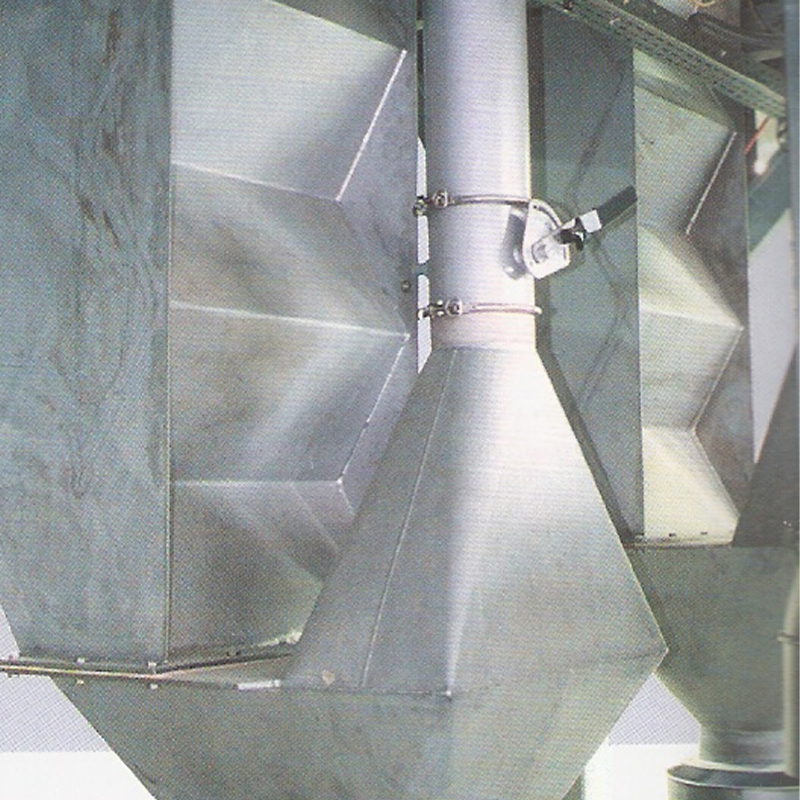

· The material is fed from the bottom of the classifier with main air stream.

· It has numerous classifier wheels, but only use one fines outlet.

· The classifier wheels run at the same speed controlled with one frequency convertor.

· Optimized labyrinth and air-purging sealing to achieve no oversize particles.

· A secondary air helps dispersion and rinsing of the feed material.

· Adjustment of cut point by variable rotors’ speed with only one frequency converter.

· Belt drive or direct drive is used depending on the size of the motor.

· Robust construction manufactured ensures long service life.

· Airborne feeding allows the multi-wheel classifier to work with a ball mill in a closed circuit.