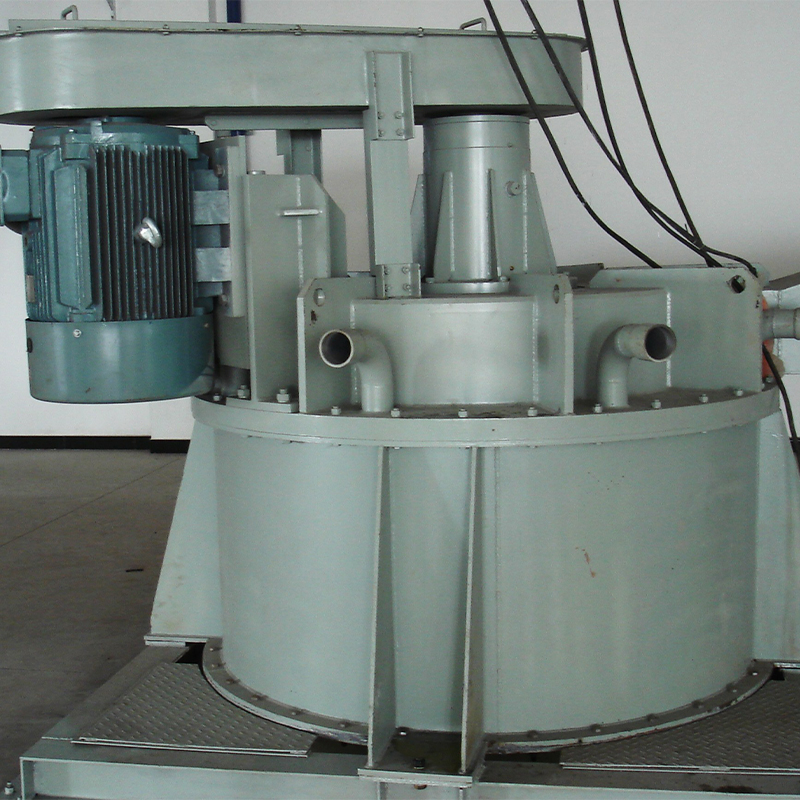

BSC Basket separator

Brand IVA Shanghai

Product origin Shanghai

Delivery time 120 days

Supply capacity 10

BCS Basket Separator

The BCS separators are equipped with a rotating basket. Similar to the DCC series of dynamic classifier, the cut point is adjusted by the speed of the rotating basket, which guaranties a “hard classifying characteristic”. That means, by variations of the feed rate the cut point does not shift. These basket separators are designed to handle high air flow rates with big mass, with a target to classifying large quantity of fine or medium coarse products, such as fly ash, slags, fine-cement, mineral fillers, tailing from ore dressing, industrial solid waste etc.

The advantage:

-Capability to handle a variety of products with feed rate from 30t to 200t per hour.

-Guide vanes leading to efficient dispersion and efficient classification.

-Optimal sealing guarantees sharp cut point and prevents from oversize particles.

-Hard classifying characteristics stabilizing the set cut point.

Technical data:

The feed rate is in a range of 25-200t/h

The cut point ranges from D97 25µm -200µm

Application:

mineral fillers, fly ash, slags, construction material, solid waste, fine cement … etc.

The features:

- There is a rotating basket in the classifying chamber controlled with a frequency convertor.

- The feed gravitationally from the tubes at the top of the classifier or pneumatically from the inlet at the bottom of the classifier

- The configuration of guide vanes enhances the dispersion and classifying efficiency.

- The optimized design of the sealings prevent the product from oversize.

- It has two outlet channels for fast discharging the fine products.

- Same as dynamic classifiers the basket separator also has hard classification characteristics.

- Sturdy construction of body and hard steel rotating basket ensure long time of service.

Keyword: metal powder ball mill, stainless steel ball mill, dry grinding, flaky metal powder.