Static classifier

Brand IVA

Product origin Shanghai

Delivery time 90days

Supply capacity 15

The SSC series of static classifiers:

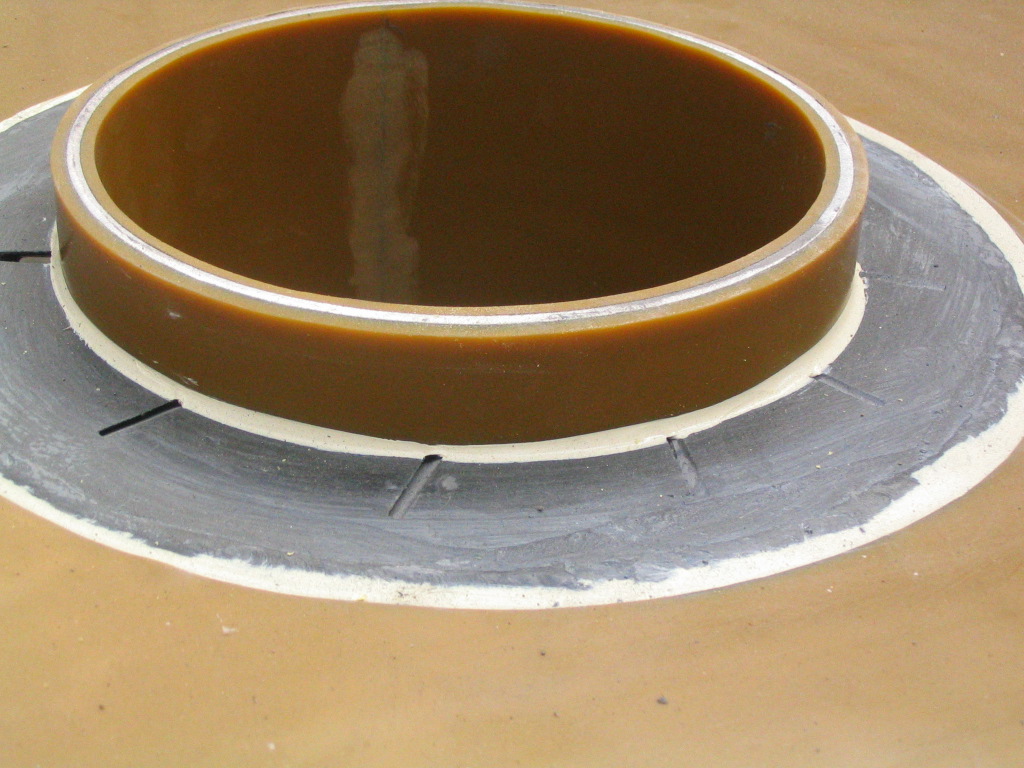

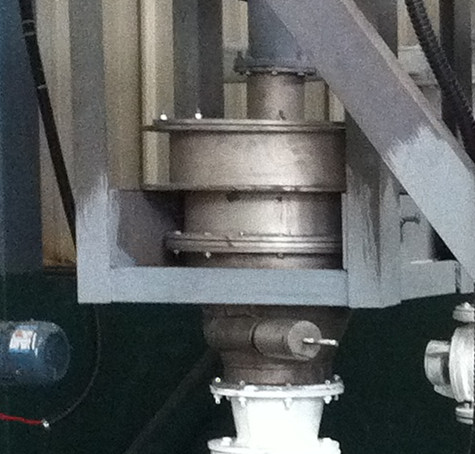

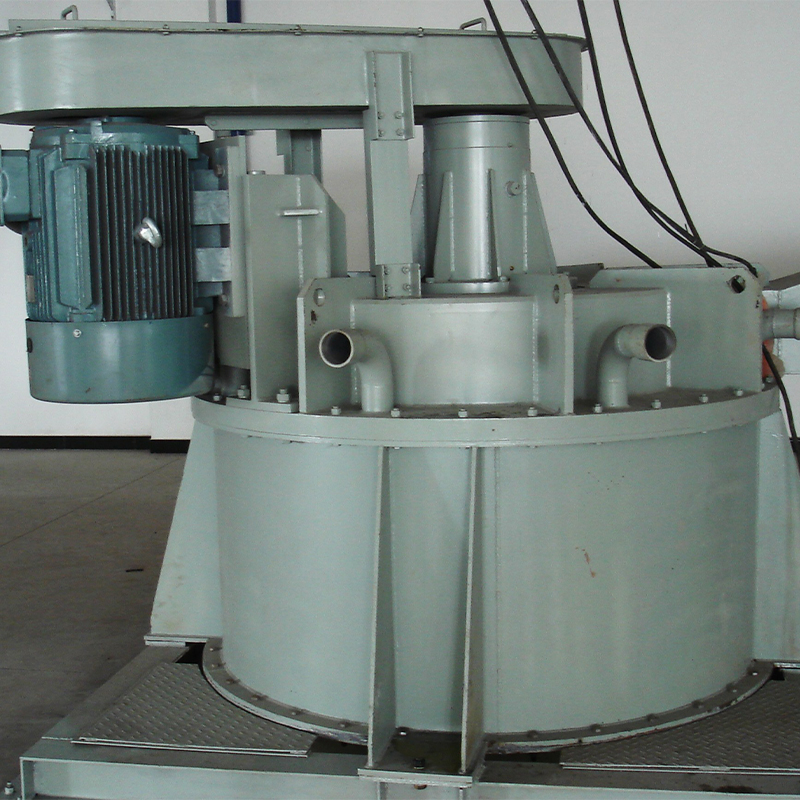

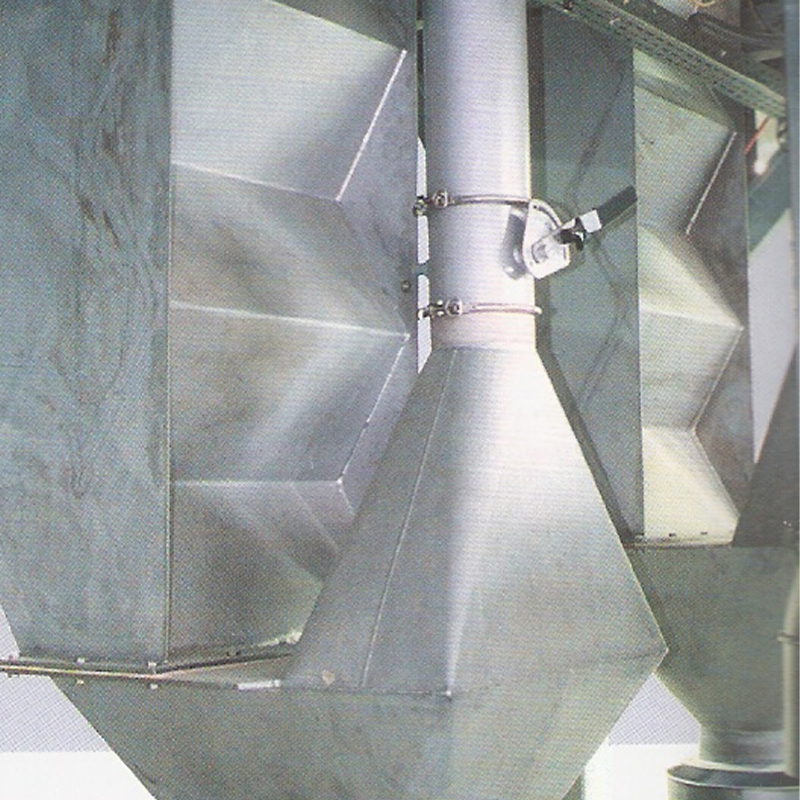

In cooperation with the specialist of Germany we have invented a new type of static classifier. This SSC series of static classifiers is designed with the principle of free vortex flow. As its name indicates, there are no rotating parts. Therefore, it is easy to be equipped for wear protection to achieve iron-free product. Additionally, it adapts to special requirements and can operate with hot gas or cooling air.

The optimal spiral flow in combination with an efficient rinsing and quick discharge of the coarse particles guarantees a fine product free of oversize particles as well a clean coarse fraction. The SSC static classifier can achieve a sharpness of cut point nearly as good as a much more expansive multi-wheel classifier.

The product is fed airborne, that allows an inline production with a mill or a dynamic classifier, i.e. to perform a two-stage classification. The airborne principle enables a closed air circulation. For fines collection a cyclone is sufficient, filters are not necessary.

Two simple possibilities of adjustment in combination with a quick change of one or two parts enable the classification to cover a wide range of cut points.

According to the mentioned above advantages the SSC classifiers are suitable for a very wide field of applications. It is predestined for

Process Applications:

· De-dusting (to get clean particles without dust)

· scalping (to separate a small amount of very large particles)

· pre-classification (to optimize the main classification process by rejecting either fines or coarse)

Product Applications:

abrasives (i.e. pure quartz, feldspar ...etc.)

food (especially with high content of fat)

metal effect pigments (“flakes”, must be carefully handled)

high temperature material (carbon black, chemicals)

Technical data:

The feed rate is in a range of 20kg to 6000kg/h

The cut point ranges from D97 5µm-120µm

Features:

· The static classifier has neither wheel nor motor, resulting in energy saving and low running cost.

· It is easy to be wear protected for hard mineral processing to get iron-free product.

· Simple and easy repairing on-site saves maintenance cost and time.

· This static classifier covers a wide range of cut points by simple adjustment.

· Thestatic classifier can achieve a sharpness of cut nearly of product which is as good as that from a much more expansive multi-wheel classifier.

· The static classifier can be inline with a dynamic classifier to perform two-stage classification.

· For fines collection a cyclone is sufficient, filters are not necessary.

Process Applications:

· De-dusting (to get clean particles without dust)

· scalping (to separate a small amount of very large particles)

· pre-classification (to optimize the main classification process by rejecting either fines or coarse)

Product application:

· abrasives (i.e. quartz, pegmatite, feldspar, granite, ceramics…etc.)

· food (especially with high content of fat)

· metal effect pigments (“flakes” particles)

· high temperature material

Technical data:

The feed rate is in a range of 20kg to 3500kg/h

The cut point ranges from D97 5µ-m120µm