-

Hot

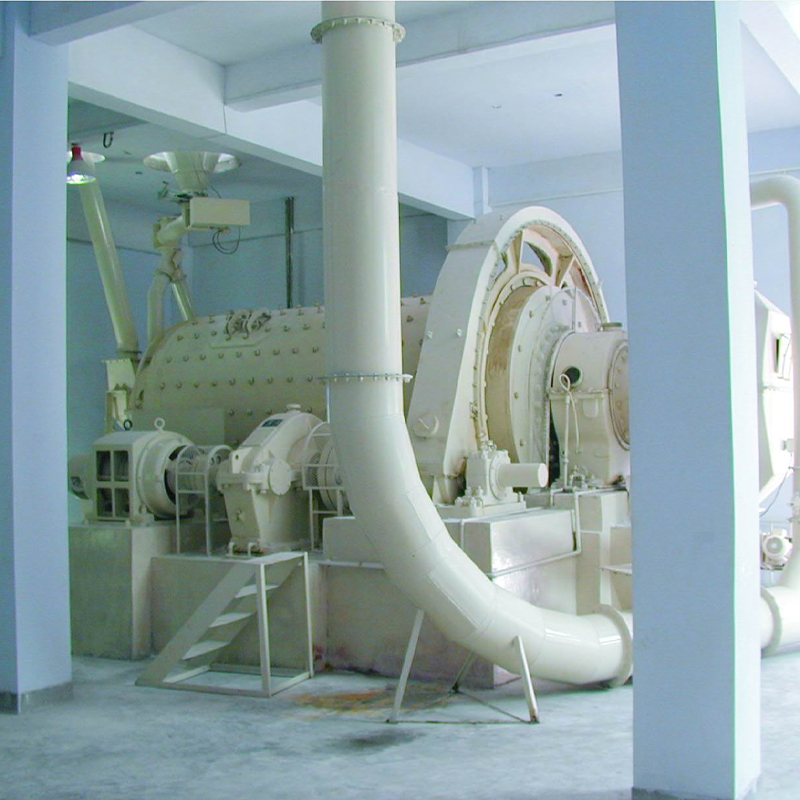

Ground calcium carbonate (GCC) ball mill

Ground calcium carbonate (GCC) ball mill A group of minerals named calcium carbonate which is usually ground and used as white fillers in plastic, rubber, paints and many other industrial fields. A dry grinding ball mill is commonly applied to the grinding process. However, the configuration of the ground calcium carbonate (GCC) ball mill is totally different from that of tube mill of cement industry. The mechanism of grinding takes place with minimum of impact and attrition energy. The products from the ground calcium carbonate (GCC) ball mill has wide range of products with quite lot of fine and ultra-fine particles which cover the versatile demand in filler market with quantity supply. These characteristics determine the important position of ball mill in the ground calcium carbonate (GCC) market. It has the following advantages: -An economic way for mineral fillers production -Suitable for large-scale industrial production -Supplier with quantity qualified products to end users -Environment friendly design

Send Email Details -

Hot

Ground silica ball mill

Ground silica ball mill Due to low-speed rotation the ball mill is an ideal device for grinding hard and abrasive minerals, such as silica, quartz, feldspar, pegmatite, ceramic raw material and other hard minerals. The inside of the drum is well protected with alumina lining or silexite blocks for iron-free production. Furthermore, our unique dry grinding ball mill of tailor-made design to work together with our newly invented static classifier becomes the best economic solution for processing silica, pure quartz as well as other hard minerals. The advantages as follows: -Energy saving design --Iron-free production -Consistent quality - Environment friendly and safety

Send Email Details -

ceramic ball mill

Feldspar, quartz, zircon, pegmatite are important raw material for production of glass, ceramic and porcelain products. The Mohs hardness of those rocks is ranging from 6-7, so the milling machines with high speed are not suitable for the grinding. Due to low rotating speed the ball mill becomes an ideal grinder. Additionally, the ball mill is easy to be protected with anti-wearing material, therefore it becomes the classical grinder for the ceramic industry. It has the following advantages: - Tailor-made based on the grindability of the feed material and the required product fineness for energy saving. - Well protected with anti-wearing material in side the mill for iron-free production. - A suction opening at the end of the mill makes dust-free and safe operation. - Robust construction for long serving life-

Send Email Details -

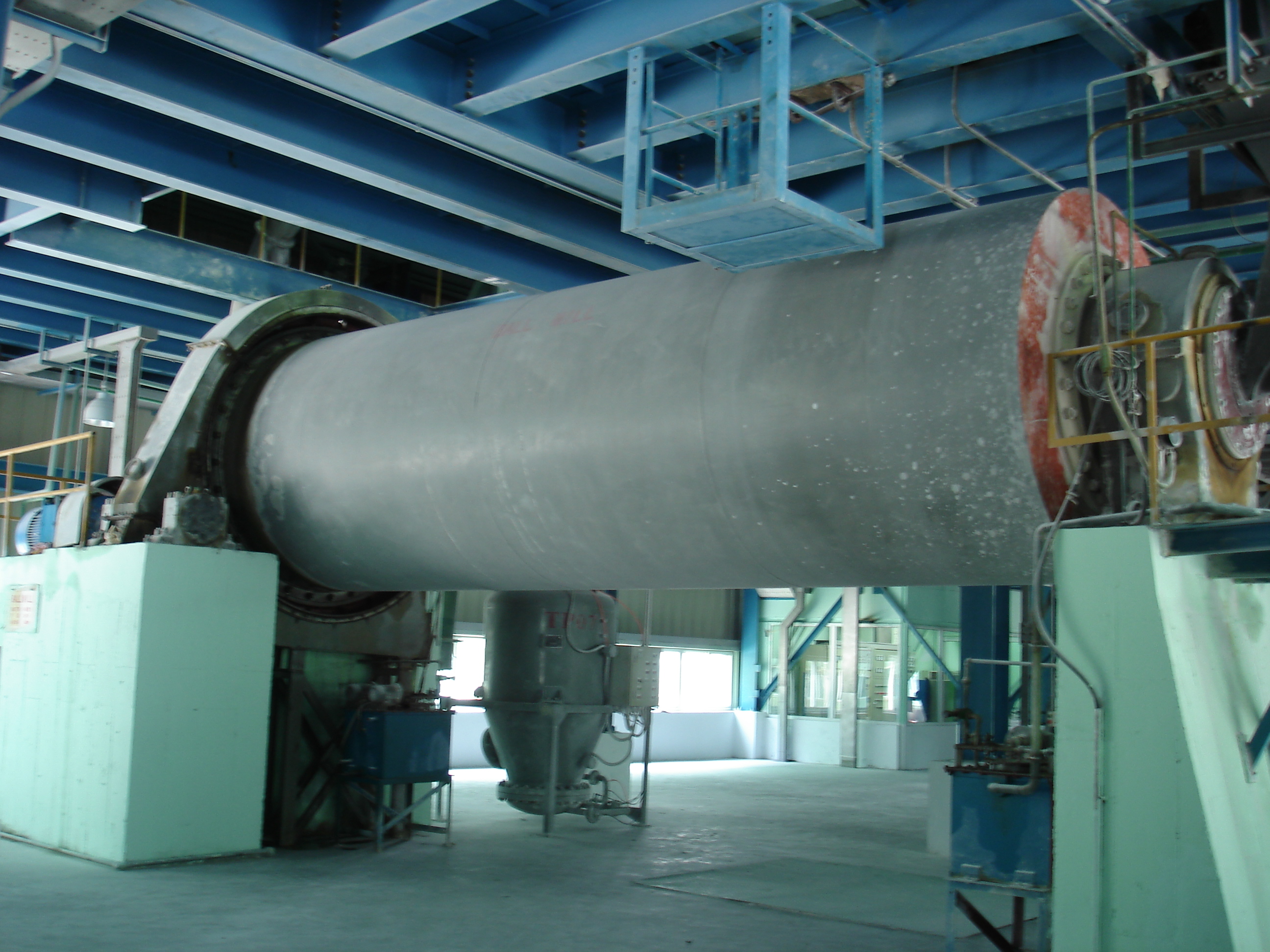

Ball mill for construction material

Cement additives, such as fly ash, slags, and construction waste have to be ground and recycled. Normally large quantity of those materials have to be treated to supply the market. Owing to the fact that ball mill can produce very fine products with large quantity throughput it is suitable for production of a variety of construction material and construction waste. The ball mill has the following advantages: -Tailor-made design according to the material property and the output -Continuous dry grinding offering stable product quality -No dust emission during operation because the mill has a suction opening at the end of it -The motor size matching the grindability of the material so as to save energy -Sturdy structure for long time service

Send Email Details -

White mineral fillers ball mill

White mineral fillers ball mill Limestone, calcite, marble, dolomite, chalk, talc …are raw material of white mineral fillers. By fine grinding they reveal high whiteness and fineness, which allow them to be used as fillers in plastic, paper, paint, coating, pharmaceuticals and many other industries. During the preparation ball mill is commonly used to grind them in a dry method. Ball milling shows a lot advantages over many other grinding machines in both product quality and quantity.- - Tailor-made deign achieving high grinding efficiency and lower energy consumption. -Constant feeding resulting in consistent quality -No dust leakage during production because an aspiration opening leading the dust to the mass flow -The mill highly loaded with cylpebs enhances the grinding efficiency - A dosing pump delivers grinding aid for fine and ultra-fine grinding - .

Send Email Details -

fly ash ball mill

Fly ash Ball mill Fly ash is an industrial waste, but it is also a kind of mineral resource that can be recycled. The most common utilization is used as additives in the cement industry. However, fly ash has a lot of more valuable applications. If the product is supplied to the plastic, coating industries...etc. it has to be ground to the required fineness, then ball mill is the right solution. The fly ash ball mill has the following advantage: -Dry grinding is used for continuously producing quantity of fine products. -The mill's diameter and length ratio is optimized to avoid over grinding. - High load of grinding media increasing grinding efficiency - An aspiration design at the end of the mill ensures environment friendly operation -Robust construction for long serving life.

Send Email Details -

Ball mill for Flaky metal powder processing

Flaky metal powder ball mill Flaky metal powder has wide application in painting, coating and printing industries. Comparing to wet grinding the dry grinding method with a ball mill is an economic solution to produce a variety of flaky metal powders. This ball mill is designed for making flaky metal powder of Cu. Al, Zn, alloyed steel and many other metals. It has the following advantages: -Continuous dry grinding saving production cost -Steel lifters instead of steel liners -Load cells under the ball mill for accurate feeding -Air swept discharging for cooling -High diameter/thickness ratio -Environment friendly and safety

Send Email Details -

Ultra-fine mineral fillers ball mill

Ultra-fine fillers ball mill With the rapid development of science and technology the mineral fillers have to be finer and finer. The cement tube ball mill cannot meet the requirement. Our practice has proved that only tailor-made ball mill with special design can fulfill the task to achieve fine or ultra-fine calcium carbonate fillers. The advantages: -Innovative design for production of fine and ultra-fine mineral fillers - The optimal diameter length ratio avoiding overgrinding. -More fine content in the ground product due to highly-loaded cylindrical grinding media - A dosing pump deliver grinding aid regularly for dispersion of the ground product -In line with a multi-wheel classifier to produce large quantity of fine products -environment friendly because of an suction opening after the slot wall -An economic solution of white mineral fillers production

Send Email Details -

quartz powder ball mill

Quartz powder ball mill Quartz is an important raw material in glass industry. With the fast development of hi-tech products quartz sand or quartz powder have found wide application in those high value-added products, such as TV screens, solar panels, semi-conductors…etc. Restricted by its special property and strict requirement on the ground products Our innovative ball mill become a preferable choice among the processing equipment. It has the following advantages : -Dry grinding saving production cost -Well protected with anti-wearing material for iron-free grinding -Constant feeding and consistent quality. -Environment friendly and safety for health via different measures of dedusting -The motor size matches the specific grinding energy resulting in energy saving.

Send Email Details -

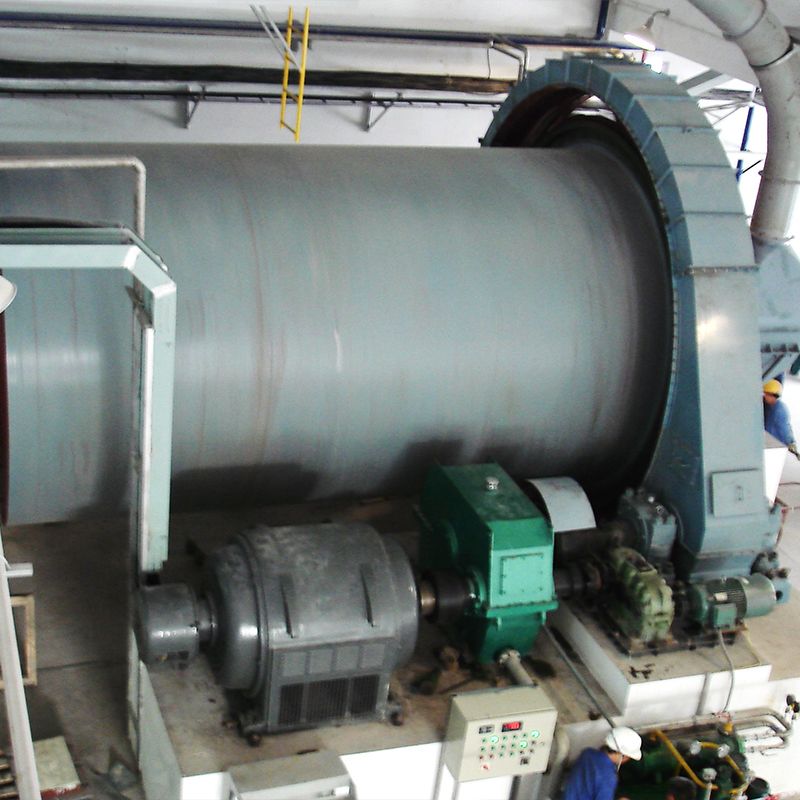

Dry grinding ball mill

Dry grinding with a ball mill is commonly used to produce calcium carbonate fillers. It produces fine or ultra-fine products continuously with quantity output and constant quality. The dry grinding ball mill can meet the high market demand on fine or ultra-fine mineral fillers used in plastic, rubber, paper and many other industries. Additionally, dry grinding ball mill is an economic choice comparing to wet process. It has the following advantages: -Comparing to wet grinding it has low running cost - Less peripheral facilities reducing investment -Wide range of cut points to meet diverse market needs -Environment friendly -Less space occupation Besides, dry grinding is also a preferable choice for ground silica, feldspar, flaky metal powder processing.

Send Email Details