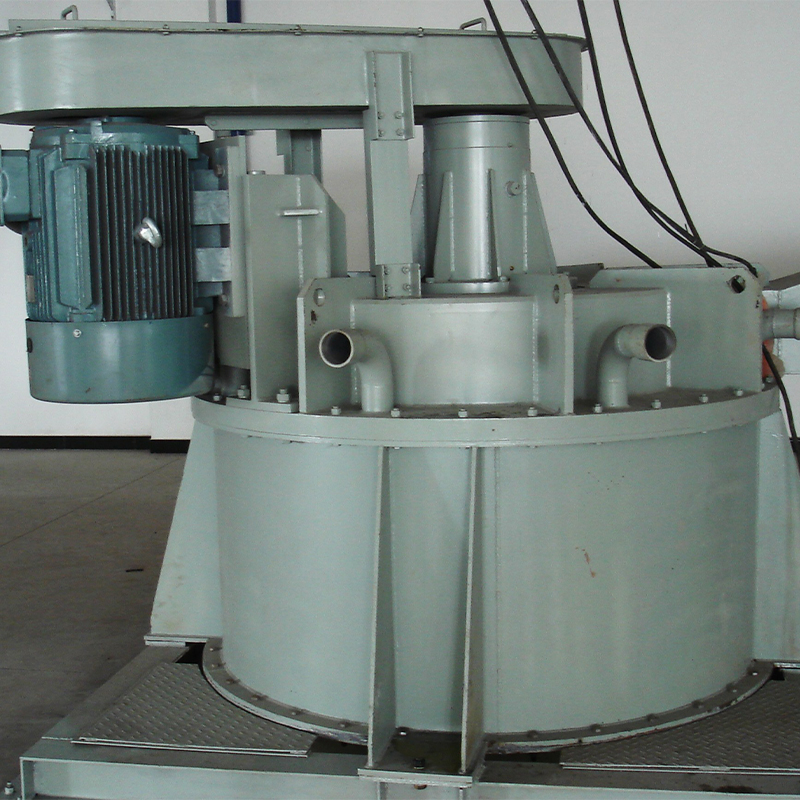

turbo classifier

Brand IVA

Product origin Shanghai

Delivery time 90 days

Supply capacity 10

The turbo classifiers belong to so-called air classifiers or dynamic classifier. It consists three parts: the classifier chamber at the top with one wheel of vertical arrangement, the secondary air inlet in the middle and the lower part, a cone for feeding and discharging of the reject. Owing to the double sealing there is no oversize particles in the products. Meanwhile, the wide range of cut points are easily and exactly adjusted by the speed of the wheel control with a frequency converter. Therefore this type of air classifiers dominate the market of powder processing for almost every product. A more important advantage is the “hard classifying characteristic”. That means, even though variations of the feed rate occurs the cut point almost does not shift. This performance predestines the turbo classifier to be used in grinding-classifying-circuits.

Technical data:

The feed rate is in a range of 0.3t – 20t/h

The cut point ranging from D97 3µm-150µm

Applications:

Mineral fillers, chemicals, pigments, paint, toner, silica, ceramic, abrasives, metal powder, foodstuff, pharmaceuticals, fly ash, solid waste...almost all kind dry powders products.

Turbo classifier Features:

The turbo classifiers are designed on the airborne principle.

The feed material is transported pneumatically, along with the main airflow, into the classifier chamber where the classifiaction takes place.

A secondary air flow is utilized for rinsing and de-agglomeration to increase classifying efficiency.

The cut point is easily and accurately adjusted by the speed of the classifier wheel which is controlled with a frequency converter.

This turbo classifier maintains a stable cut point even if the feed rate is fluctuated.

The optimized labyrinth and air rinsing system guarantee that no oversized particles are present in the final product.

The classifier wheel can be driven diectly by a motor or connected via a belt depanding on the motor size.

Various options for wear protection are available for the internal components in order to be used for abrasive material classification.

The robust structure ensures a long service life, providing reliable operation over time.

Owing to its "hard classifying characteristics" the classifier is preferable to work with a mill to forms a closed grinding-classifying circuit, enhancing overall production efficiency.