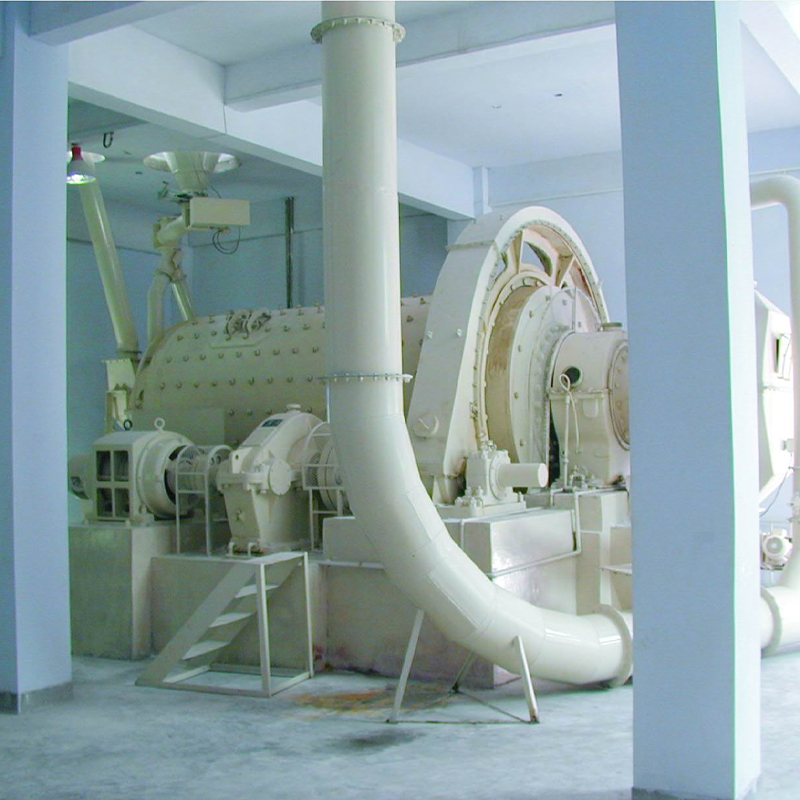

Dry grinding ball mill

Brand IVA Shanghai

Product origin Shanghai

Delivery time 90 days

Supply capacity 10

Dry grinding with a ball mill is commonly used to produce calcium carbonate fillers. It produces fine or ultra-fine products continuously with quantity output and constant quality. The dry grinding ball mill can meet the high market demand on fine or ultra-fine mineral fillers used in plastic, rubber, paper and many other industries. Additionally, dry grinding ball mill is an economic choice comparing to wet process. It has the following advantages:

-Comparing to wet grinding it has low running cost

- Less peripheral facilities reducing investment

-Wide range of cut points to meet diverse market needs

-Environment friendly

-Less space occupation

Besides, dry grinding is also a preferable choice for ground silica, feldspar, flaky metal powder processing.

The features:

● Comparing to wet griding the dry grinding can save energy for dewatering and drying.

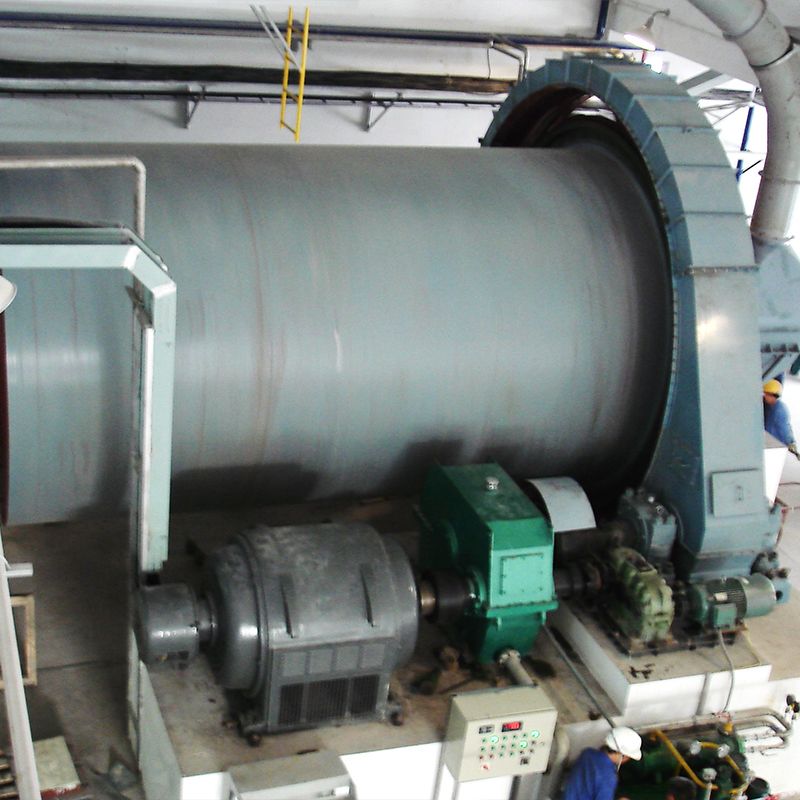

● The grate discharge ball mill is applied which enables to use finer grinding media to achieve highest performance of fine and ultrafine grinding.

● The dry grinding ball mill dedusting through the slot wall ensures optimal aspiration and lowest dust development.

● The optimal ratio of diameter and length avoids overgrinding.

● The installed driver’s energy introduced into the product as grinding energy is as high as possible.

● The placement of the drive station can be arranged freely according to the working space.

● The robust welding structure of the dry grinding ball mill makes it long serving life.