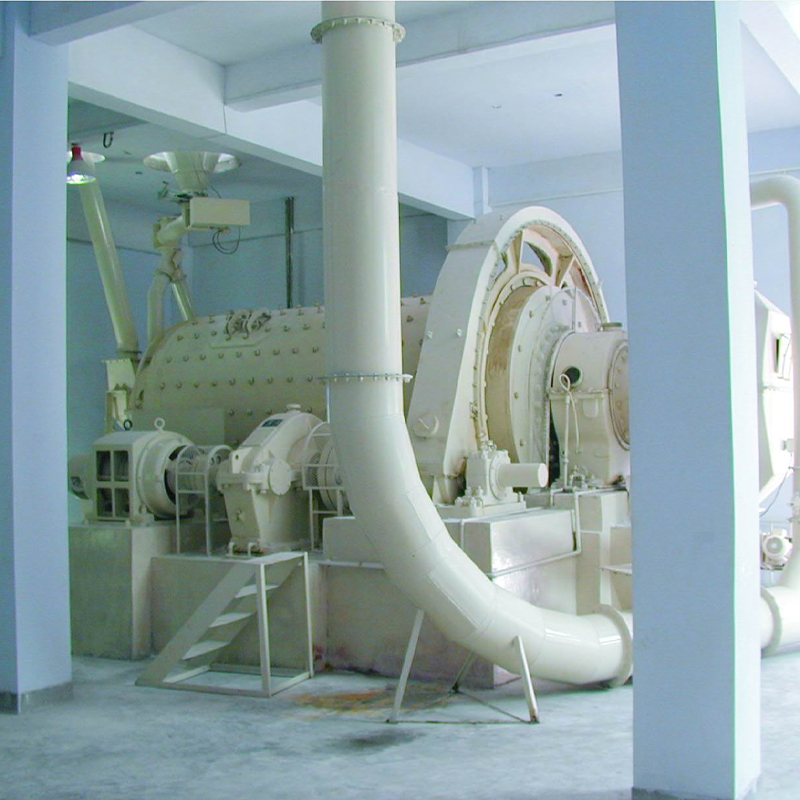

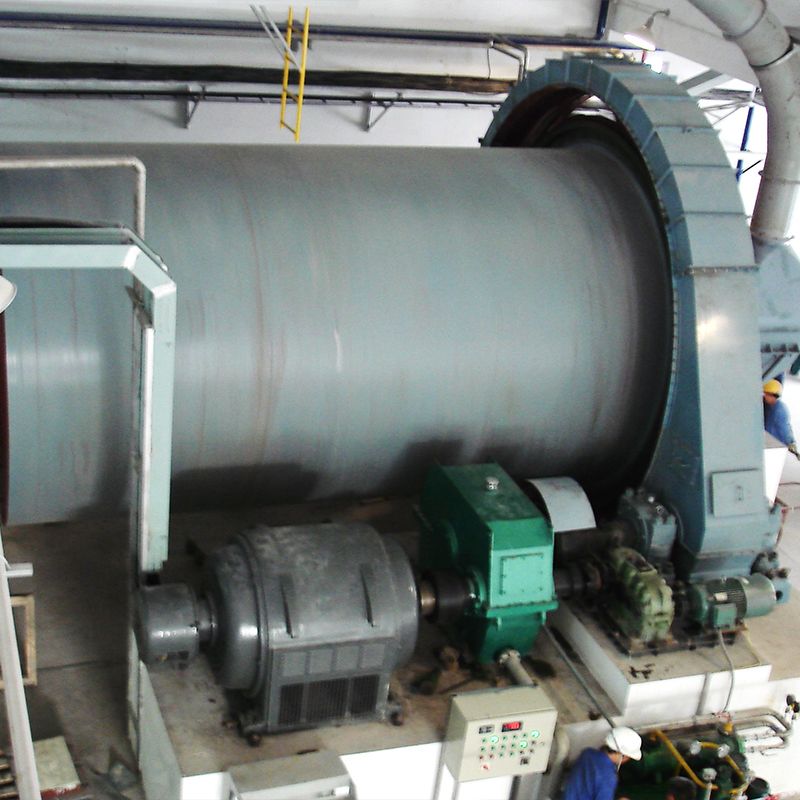

Ultra-fine mineral fillers ball mill

Brand IVA

Product origin Shanghai

Delivery time 90-120days

Supply capacity 15

Ultra-fine fillers ball mill

With the rapid development of science and technology the mineral fillers have to be finer and finer. The cement tube ball mill cannot meet the requirement. Our practice has proved that only tailor-made ball mill with special design can fulfill the task to achieve fine or ultra-fine calcium carbonate fillers.

The advantages:

-Innovative design for production of fine and ultra-fine mineral fillers

- The optimal diameter length ratio avoiding overgrinding.

-More fine content in the ground product due to highly-loaded cylindrical grinding media

- A dosing pump deliver grinding aid regularly for dispersion of the ground product

-In line with a multi-wheel classifier to produce large quantity of fine products

-environment friendly because of an suction opening after the slot wall

-An economic solution of white mineral fillers production

The features:

● Comparing with other types of grinding machines ball milling get more fines in the grinding process.

● Otipmal L/D ratio to prevent the mill from overgrinding.

● Cylindrical grinding media create more friction and attrition on the material to get more fine and ultrafine calcium carbonate content.

● The slot wall allows the drum highly loaded with smaller grinding media.

● Highly loaded fine grinding media increase the grinding efficiency of fines.

● A dosing meter is installed to spray grind aid for deagglomeration of the product.

● A suction opening is designed at the end of the mill to catch the dust and send it back to the mass flow.

● The motor size matches the grinding energy of the raw material to save energy.