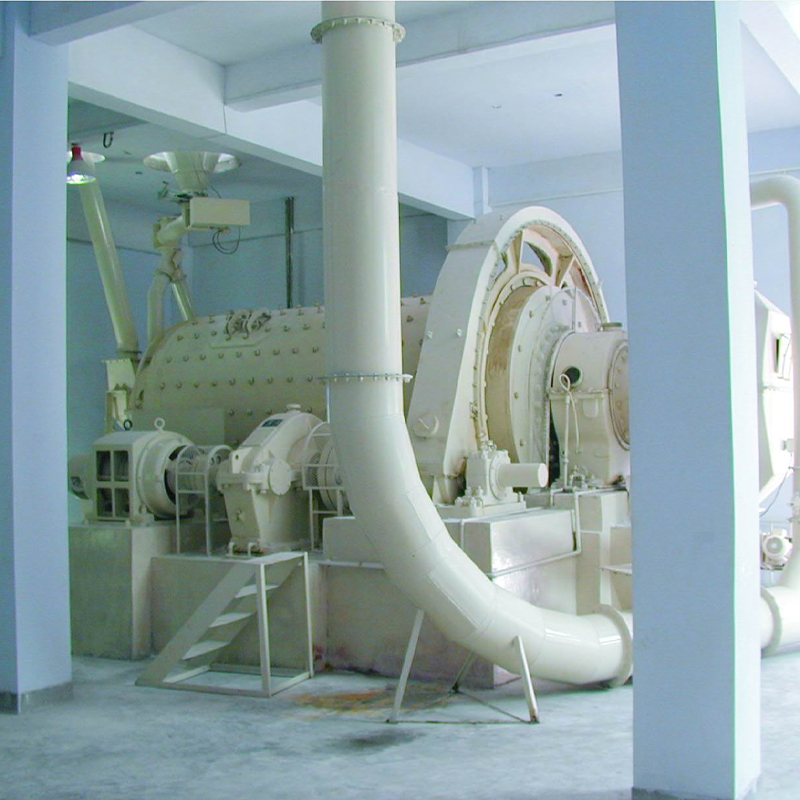

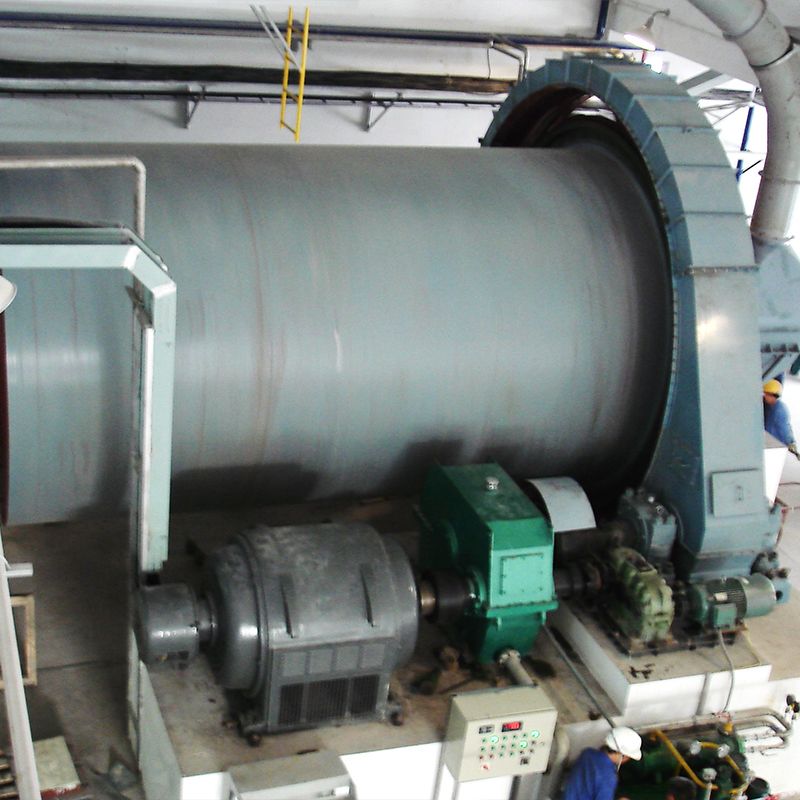

ceramic ball mill

Brand IVA Shanghai

Product origin Shanghai

Delivery time 90-120 days

Supply capacity 15

Feldspar, quartz, zircon, pegmatite are important raw material for production of glass, ceramic and porcelain products. The Mohs hardness of those rocks is ranging from 6-7, so the milling machines with high speed are not suitable for the grinding. Due to low rotating speed the ball mill becomes an ideal grinder. Additionally, the ball mill is easy to be protected with anti-wearing material, therefore it becomes the classical grinder for the ceramic industry. It has the following advantages:

- Tailor-made based on the grindability of the feed material and the required product fineness for energy saving.

- Well protected with anti-wearing material in side the mill for iron-free production.

- A suction opening at the end of the mill makes dust-free and safe operation.

- Robust construction for long serving life-

The features:

- The ceramic ball mills are tailor-made according to the material grindability and product capacity.

- The L/D ratio of the drum is optimized with purposes of preventing from over-grinding.

- An aspiration opening at the end of the ball mill is designed for de-dusting and cooling.

- Ceramic bricks and tiles are paved inside of the ceramic ball mill for protection of the drum and prevention of contamination of the product.

- The installed drive of the ceramic ball mill matches the specific energy consumption of the product perfectly resulting in energy saving.

- Solid construction of the ceramic ball mill with anti-wearing lining offers long serving time with low maintenance cost.

- The drive station may be arranged freely to fit the limited working space